FREEFORM ON THE OUTSIDE,

PURE IN THE INSIDE

Sustainable Additive Manufacturing

for high-quality metal and ceramic parts.

TECHNOLOGY

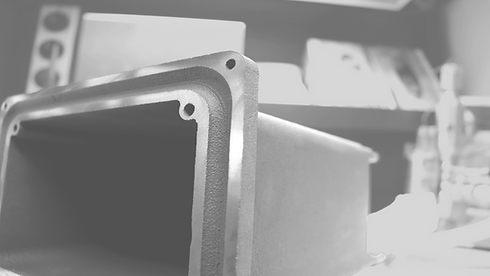

3D-PRINTED SHELL CASTING

voxelcast' innovation is a combination of the best advantages from two established production technologies:

3D-printing + slurry-casting

🟅 More flexible system

🟅 More efficient process

🟅 More economical approach

2. CASTING

1. SHELL

3D-PRINTING

3. THERMAL DEMOLDING & SINTERING

BENEFITS

Enabling metal & ceramic capabilities in an efficient, low footprint & user-friendly setup

FLEXIBLE+AGILE

PRODUCTION

Our efficient workflow is powered by a modular concept that makes use of tested and proven hardware systems, integrated digitally.

Already have a photopolymer 3D printer? You can now use them to produce high-quality metal & ceramic parts.

With substantial reduction in setup investment cost compared to other metal or ceramic 3D printers, our technology can achieve maximum adaptability in production without any risk of expensive machines becoming obsolete.

HIGH-PURITY CAST MATERIAL

By innovating the process and workflow, we can utilize high-purity cast material with minimal binder content.

This eliminates the limitations and wastage of resources caused by the debinding issues in the mainstream metal & ceramic sinter-based AM.

EXCELLENT SURFACE OUTCOME

A clean process is beneficial not only for the environment, but also for the production outcome. With minimal contamination in the process steps, we can achieve exceptional aesthetics without post-processing.

SINTERPURE

Our complete AM system also includes the advanced sintering solution.

Another one of our patent-filed breakthrough allows for precise control of the inner atmosphere in compact lab ovens.

Sinter parts on-demand and benefit from significant gas savings during the sintering process of reactive materials,.